Products

In-Tank Equipment

Bi-Directional Jet Aerators

The Mass Transfer Systems bi-directional jet aerators are designed with jet aeration nozzles installed on both sides of the liquid / air jet aeration manifold. This configuration is most applicable for square or rectanglular tanks, larger lagoons, and sequence batch reactors where directional flow patterns are not desired.

Directional Jet Manifold Aerators

The Mass Transfer Systems directional jet aerators are designed with jet aeration nozzles installed on only side of the liquid / air jet aeration manifold. This configuration is most applicable for round tanks, lagoons, and ditches where directional flow patterns can be achieved to aid in the mixing of the tank contents.

Radial Jet Pod Aerators

The Mass Transfer Systems radial jet pod aerators are designed with jet aeration nozzles installed around the circumference of an integral liquid / air pod body. This configuration is most applicable for smaller round and square tanks and sequence batch reactors where directional flow patterns are not desirable.

Retrievable Jet Aeration Skids

Where aeration is required and the process tank cannot be emptied in order to install a traditional jet aeration system, Mass Transfer Systems offers skid mounted wet installed retrievable jet aeration systems. The systems can utilize a submersible pump mounted on the retrievable skid or a dry pit pump mounted outside of the tank.

Rotating Equipment

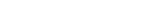

Liquid Recirculation Pumps

The Mass Transfer Systems bi-directional jet aerators are designed with jet aeration nozzles installed on both sides of the liquid / air jet aeration manifold. This configuration is most applicable for square or rectanglular tanks, larger lagoons, and sequence batch reactors where directional flow patterns are not desired.

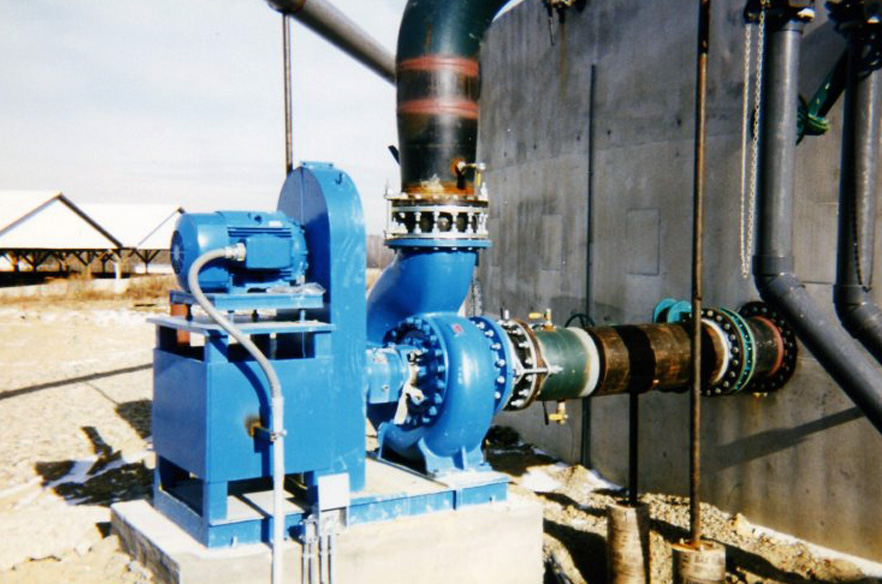

Air Blowers

Mass Transfer Systems offers the air blowers for the aeration systems. The bulk of the blowers normally supplied are either multi-stage centrifugal or positive displacement blowers. As with the pumps, MTS can provide the pumps as part of our package or we can provide technical assistance in the selection of the best fit blowers for the project.

Jet Mixing Systems

Jef Mixing Systems

The MTS jet mixing systems are a highly turbulent submerged mixer technology. Jet mixing is a highly efficient method to distribute mixing energy while minimizing horsepower requirements. Each MTS mixing jet nozzle consists of of two liquid nozzles nested together. The primary flow is typically provided by either a dry-pit or submersible pump that draws suction from the tank being mixed.

Aspirator Self-Aspirating Submersible Aerator

The MTS Aspirator provides oxygen transfer by aspirating the ambient atmospheric air, thus negating the need for air blowers.

Floating Effluent Decanters

Mass Transfer Systems offers a line of floating effluent decanters. The MTS design utilizes a swing joint that allows for a wide range of decanting. The standard material of construction for the decant arm is stainless steel. Fiberglass construction is available as an option.